Safety and morale or smoke and mirrors…

Some workplaces talk a big game about safety. Posters on the walls. Slogans in emails. Maybe even a “Safety First” banner hanging in the breakroom. But when you look closer, it’s all for show. That’s safety theater, where rules exist on paper, but not in practice. Real safety culture is different. It’s not about looking compliant, it’s about keeping people alive.

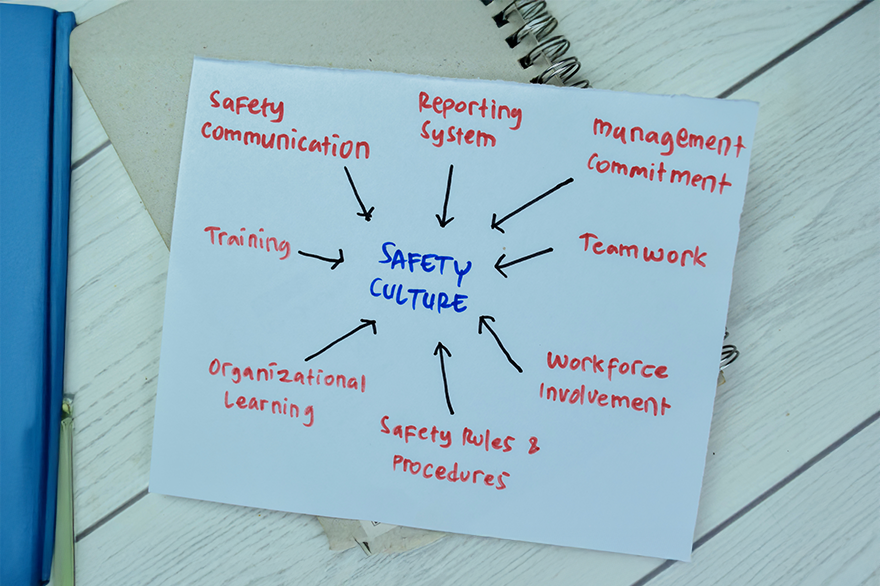

True safety culture means workers don’t just follow rules because they have to. They follow them because they understand why they exist. It’s a shift from treating safety as a burden to seeing it as a necessity. Companies that only focus on appearances end up with workers who go through the motions. Meanwhile, real hazards remain unchecked. When that happens, it’s not a question of if an accident will happen, but when.

The Difference Between Culture and Theater

Safety Theater refers to policies that look good on paper but don’t actually prevent accidents. These include excessive paperwork, pointless PPE rules, and outdated procedures that nobody follows. By contrast, Safety Culture is when workers at every level prioritize safety. They don’t just talk about safety. They take real steps to make it part of daily work and decision-making. In a strong safety culture, workers have the confidence to stop unsafe work. Shortcuts aren’t ignored, and training is more than just a requirement, it’s a priority.

A strong safety culture means workers feel empowered to stop unsafe work. It means shortcuts don’t get ignored. It means training isn’t just a formality, it’s a priority.

When safety theater takes over, companies create a false sense of security. Workers may assume they’re safe just because procedures exist. But if those procedures aren’t tested or enforced, they mean nothing. Real safety culture isn’t about checking boxes. It’s about making sure every worker goes home safe.

Signs of Safety Theater

Some companies think they’re prioritizing safety, but they’re really just checking boxes. Here’s how to tell the difference:

- Endless paperwork, but no real enforcement. If reports are filed but hazards don’t get fixed, it’s just theater.

- Workers afraid to report safety issues. If speaking up means punishment or being ignored, safety is just for show.

- Lip service from leadership. If managers push productivity over safety, their real priorities are clear.

- Outdated or irrelevant training. If workers aren’t learning anything useful, the training is just a box to check.

- Focus on blaming workers instead of fixing systems. Real safety looks at root causes, not just who messed up.

- No follow-through after incidents. If accidents happen but nothing changes, safety is not a real priority.

- One-size-fits-all rules. Every industry has different risks, blanket policies don’t address real hazards.

- More concern for compliance than real protection. Following the law is important, but real safety goes beyond minimum requirements.

The Hidden Costs of Safety Theater

A company that treats safety as a performance rather than a practice is playing a dangerous game. The hidden costs of safety theater go beyond injury rates:

- Employee disengagement. When workers know safety is just a show, they stop taking it seriously.

- Regulatory trouble. Compliance officers see through the act. Companies that fake safety will eventually face fines or shutdowns.

- Increased turnover. Employees don’t stay where they don’t feel safe. High injury rates lead to high quit rates.

- Legal liability. Faking safety won’t hold up in court. Companies can be sued for negligence if they fail to protect their workers.

Building a Real Safety Culture

Fixing safety theater takes real commitment. Here’s how workplaces can shift from performance to protection:

- Empower Workers to Speak Up. Workers should feel safe stopping work if they see something unsafe. They must trust that reporting hazards won’t lead to retaliation.

- Prioritize Training That Matters. Skip the generic safety videos. Teach workers about the specific risks they face daily.

- Fix Problems, Don’t Just Document Them. Reporting a hazard isn’t enough, companies need to act on it.

- Hold Leaders Accountable. Safety starts at the top. If management isn’t following the rules, workers won’t either.

- Measure Safety by Actions, Not Paperwork. Track real safety actions like near-miss reports, hazard fixes, and worker feedback. Don’t just count how many forms get filled out.

- Encourage Realistic Safety Drills. A fire drill where everyone casually walks to an exit isn’t enough. Make drills real. Add pressure. Test workers in situations that mimic actual emergencies.

- Reward Safe Behavior. When workers make safety-conscious decisions, recognize them. Positive reinforcement builds better habits than punishment.

- Invest in the Right Safety Tools. If a workplace demands PPE, make sure it’s comfortable and practical. Workers are more likely to use gear that fits well and doesn’t hinder their job.

- Make Safety Part of Everyday Conversations. Safety shouldn’t just be a monthly meeting topic. It should be discussed on job sites, in pre-shift meetings, and during training sessions.

- Audit Safety Practices Regularly. Don’t assume policies are followed, check them. Conduct surprise safety audits and correct issues immediately.

Examples of Safety Culture vs. Safety Theater

Imagine a warehouse that claims safety is a priority. Posters cover the walls, and training sessions are scheduled regularly. But in reality, workers are pushed to meet impossible quotas. Forklift drivers neglect seat belts. Safety violations are brushed aside in the name of productivity. Eventually, an accident happens, and suddenly, all those ignored risks become real consequences.

Now, contrast that with a construction company that takes a different approach. After a close call, they don’t just sweep it under the rug. They start holding daily safety meetings and actively encourage workers to report near misses. Instead of ignoring potential risks, they address them head-on. Workers are rewarded for taking safety seriously, reinforcing a culture where speaking up is valued. Over time, injuries decrease, and workers become more engaged in safety efforts. The company earns a reputation for prioritizing protection over production speed. The difference between safety culture and safety theater is simple. One is a performance for appearances, while the other is a commitment to real safety.

The Cost of Getting It Wrong

When companies fail to move beyond safety theater, the consequences are real. Accidents don’t just cause injuries, they shut down operations, cost money, and destroy reputations.

- Legal Consequences: Failing to follow safety regulations can result in fines, lawsuits, and even criminal charges.

- Increased Turnover: Workers don’t stay where they don’t feel safe. High injury rates drive employees to seek jobs elsewhere.

- Lost Productivity: When accidents happen, work stops. Equipment needs repairs. Investigations slow everything down.

- Reputation Damage: A company known for unsafe practices struggles to attract skilled workers and contracts.

Safety culture isn’t about convenience, it’s about survival. Companies that cut corners on real safety will pay the price in injuries, lost productivity, and legal trouble.

Final Thought: When Safety is Real, Workers Know It

Workers can tell when safety is just a performance. They know if they’re actually protected, or if they’re one accident away from being blamed. Real safety culture doesn’t rely on slogans. It relies on action.

A safe workplace isn’t the one with the most paperwork. It’s the one where workers go home in one piece, every single day. Companies that take safety seriously earn trust and reduce accidents. They create workplaces where employees aren’t just doing their jobs, they’re doing them safely.

Related Articles

- All Posts

- #EmergencyPreparedness

- 2025 safety trends

- 360 Immersive

- 360immersive

- 6S Safety

- accident prevention

- accidental careers

- accountability

- adjustable workstations

- adult education

- AFAD

- AI automation

- AI implementation

- AI in business

- AI in operations

- AI in Safety

- AI podcast

- AI strategy

- AI transformation

- Airborne Hazards

- Alberta safety

- Alberta safety courses

- Allan James Moore

- Anhydrous Ammonia

- artificial intelligence

- asking for help

- audit findings

- audit readiness

- Audit Reporting

- automated compliance workflows

- automation in safety

- automation strategy

- avoidable injuries

- awareness

- Aztec Safety

- back strain

- BambooHR integration

- Bear safety

- behavior-based safety

- Behavioral Safety

- behavioural safety

- best EHS software for Canada

- biometric sensors

- BIS Podcast

- BIS Safety Podcasts

- BIS Safety Software

- BIS Safety Spotlight

- black holes

- Blame Culture

- Blue Angels

- Boom Lift Safety

- BP Texas City Explosion

- Brave Leadership

- Brett Burkard

- bump test

- burnout

- business automation

- calibration

- call before you dig

- Canadian Compliance

- Canadian OHS

- Canadian safety

- Canadian safety history

- Canadian Safety Regulations

- Canadian safety standards

- Canadian wilderness safety

- CAPA tracking system

- carbon monoxide

- Cargo Securement

- Carolynne Heron

- CCOHS

- Change Management

- chemical

- Chemical Safety

- chemical vapors

- chronic injuries

- chronic pain

- cloud-based safety tools

- Coming Soon

- Commercial Drivers

- Commercial Vehicle Safety

- Communication in Safety

- Communication Systems

- community safety programs

- Competency in Safety

- Competency-Based Training

- complacency in safety

- Compliance

- compliance courses

- Compliance In Canada

- compliance issues

- Compliance management

- Compliance Reporting

- compliance software

- compliance software providers

- compliance tools

- compliance tracking

- compliance training

- compliance vs protection

- confined space

- Confined Space Safety

- connected safety systems

- Construction advocacy

- Construction education

- Construction industry

- construction safety

- construction safety training

- construction technology

- ConstructionSafety

- continuous improvement

- continuous safety improvement

- Continuous Safety Training

- COR safety software

- corporate culture

- corporate training

- corrective actions

- CPR and AED

- crane

- Crane and Rigging Safety

- CSA standards

- Customer Spotlight

- Customer Spotlight Kevin Swinden Global Hazmat Safety Culture Hazmat Management Dangerous Goods Competency in Safety Workplace Risk Mitigation BIS Training Clients Canadian EHS

- customized training

- daily trip inspection

- Damage Prevention

- Dangerous Goods

- dangerous goods classification

- Danny Sellers

- data-driven safety

- debriefing

- Decision Analysis

- Decision quality

- defect management

- defect tracking

- defensive driving

- DEI in onboarding

- digital badges

- digital compliance

- digital FLHA

- digital forms

- Digital Hazard Reporting

- Digital Onboarding

- digital safety

- Digital Safety Audits

- digital safety meetings

- Digital Safety Solutions

- Digital safety systems

- digital safety tools

- digital safety transformation

- digital site access

- Digital Training Tools

- digital transformation

- DMS features

- document control

- document management system

- Dr. Joanna Pagonis

- Dr. Tom Krause

- Drilling operations safety

- Driver Fatigue

- driver file management

- driver training

- driving instructor program

- DTRMS

- Duty-Time Management

- e-learning

- e-learning tools

- eadership in safety

- early intervention

- education technology

- EHS

- EHS Adoption

- EHS analytics solutions

- EHS Compliance

- EHS compliance software

- EHS demo questions

- EHS digital solutions

- EHS Inspections

- EHS leadership

- EHS Onboarding

- EHS software

- EHS software Canada

- EHS software comparison

- EHS software features for workplace safety

- EHS software for contractors

- EHS software vendor selection checklist

- EHS Strategy

- EHS system connectivity for safety excellence

- EHS systems

- EHS technology

- EHS tools

- EHS vendor review

- Einstein

- ELD

- electrical safety

- Elevated Work Safety

- elite performance

- Emergency Action Plan

- emergency preparedness

- emergency procedures

- emergency response

- emergency supplies

- emotional training

- EmpathyInLeadership

- employee behavior

- employee engagement

- employee health

- Employee onboarding

- employee preparedness

- Employee Readiness

- employee safety

- employee training

- employee trust

- Employee Well-Being

- EmployeeEngagement

- Employer Responsibilities

- Energy Isolation

- engaging toolbox meetings

- enterprise EHS platforms

- equipment inspections

- Equipment Operation

- Equipment Safety

- ergonomic consulting

- ergonomic design

- ergonomic risks

- ergonomics

- Evacuation Procedures

- evidence collection

- EWI Works

- Excavation Hazards

- Excavator Safety

- excavator safety essentials

- exoskeleton

- exoskeletons

- failing safely

- failure analysis

- fall prevention

- fall protection

- fast onboarding

- field experience

- field level hazard assessments

- field operations

- field safety

- field safety assessments

- field safety communication

- field safety leadership

- Field Safety Operations

- Field safety practices

- field safety services

- Field Safety Technology

- field safety tools

- Field-based safety culture

- Field-Friendly Software

- Fire Drills

- fire prevention

- Fire Safety Training

- first aid

- first aid kit

- first week on the job

- first workplace injury

- Fit Testing

- flaggers

- Fleet Compliance

- fleet management

- fleet safety

- FLHA engagement

- FLHA Integration

- FLHA software

- floor mats

- FMEA

- freight

- Frontline Engagement

- frontline safety

- fuel handling

- future of work

- gas detection

- gas monitors

- Gas Respirator Safety

- Gas Safety

- Global Hazmat

- global onboarding

- Good Samaritan laws

- gravitational waves

- gut feeling in safety

- hand injuries

- handling hazardous materials

- Hands-on safety management

- hands-on training

- hazard analysis

- hazard assessment compliance

- hazard assessment software

- Hazard Awareness

- hazard communication

- Hazard Control

- Hazard Identification

- hazard prevention

- hazard recognition

- hazard reporting

- hazard reporting technology

- hazard tracking

- Hazardous Energy Control

- Hazardous Materials

- Hazmat Management

- Health & Safety Podcast

- health and safety

- Health and Safety Leadership

- hearing loss prevention

- hearing protection

- heavy equipment operation

- heavy equipment safety

- Heavy Equipment Training

- hidden workplace hazards

- high voltage systems

- High-reliability teams

- High‑performance teams

- HOS Training

- Hours of Service

- HR automation

- HR software

- HR technology

- HSE leadership

- human factors

- human factors in safety

- human in the loop

- Human Performance

- human vs machine

- human-centered design

- human-centered safety

- Human-Centred Safety

- HumanCenteredLeadership

- Humble leadership

- humor in safety

- hydrogen sulfide

- ICBC certification

- ice melt

- identification

- immersive learning

- Imposter Syndrome

- incident data

- incident investigation

- incident management

- incident prevention

- incident prevention software

- incident reporting

- inclusive leadership

- industrial AI

- Industrial Hygiene

- industrial safety

- Industrial Training

- influence vs control

- Infrastructure Risk

- injury consequences

- injury prevention

- injury prevention tips

- injury recovery

- injury reporting

- injury response

- injury response plan

- inspections

- instant hazard logging

- instructor development

- internal audits

- international workforce

- interpreting safety data

- invisible dangers

- isk and compliance software

- ISO standards

- Jeff Mulligan

- Jennifer Lastra

- job site accountability

- job site hazards

- job site risks

- job site safety

- jobsite readiness

- Jody Young

- KBR Safety Training

- Kevin Swinden

- labor movement

- ladder safety

- Landscaping Ergonomics

- Landscaping Safety

- Leadership

- leadership accountability

- leadership and empathy

- Leadership by example

- leadership communication

- Leadership Development

- Leadership in Safety

- Leadership Management

- leadership messaging

- Leadership Story

- Leadership trust

- LeadershipDevelopment

- Lean Manufacturing

- Lean Workplace

- learning from incidents

- learning management

- lifting techniques

- lighting

- LIGO

- Linda Miller

- LMS

- LMS features

- LMS software

- Load Securement

- Lock Out Tag Out

- lockout tagout

- Lone Worker Safety

- lone workers

- LOTO

- LOTO Training

- machine learning

- Machine Safety

- Maintenance Safety

- Manufacturer Specifications

- mental health at work

- Mental Health in Construction

- Mentorship in Safety

- MEWP Training

- MI Safety

- microlearning

- Mike Schwartz

- Mini Excavator Training

- Mining and resource safety

- Mining Safety

- minor injuries

- mobile EHS software

- mobile FLHA solution

- mobile inspections platform

- mobile onboarding

- Mobile Safety Apps

- Mobile Safety Platforms

- mobile safety reporting

- Mobile Safety Tools

- mobile safety tools safety compliance solutions

- MOU Standards

- mould hazards

- mould prevention

- movement in workplace

- Multi-Contractor Worksites

- multilingual training

- MyZone AI

- Near Miss Reporting

- new hire experience

- New Hire Safety

- New Worker Training

- new workers

- no-blame investigations

- noise exposure

- nonconformance

- Northern BC

- NRCA

- NSC Standard 13

- occupational fatigue

- occupational hazards

- occupational health

- Occupational Health and Safety

- Occupational Health and Safety (OHS)

- occupational health risks

- occupational safety

- occupational therapy

- OH&S

- OHS

- OHS Career Advice

- OHS Compliance

- OHSA

- oil and gas safety

- omni-training

- On-Site Safety

- onboarding Canada

- onboarding safety

- Onboarding Software

- online learning

- online orientation software

- Online safety training

- operational efficiency

- Operational Excellence

- Operational risk

- Operational Safety

- Operator Certification

- organizational culture

- organizational safety

- OSHA compliance

- OSHA standards

- outdated practices

- Outdoor work hazards

- overconfidence

- overhead crane courses

- pain awareness

- paperless safety reporting

- paperless safety talks

- PDCA Cycle

- People-First Safety

- personal protective equipment

- Pharmaceutical Safety

- physics careers

- pipeline safety

- playbook software

- podcast

- post-accident review

- post-incident protocol

- PPE

- PPE enforcement

- PPE improvement

- PPE Training

- pre-trip inspection

- predictive analytics

- pretrip inspection

- Preventative Safety

- Preventing Complacency

- preventing shortcuts

- preventive action

- proactive risk management

- proactive safety

- proactive safety culture

- proactive safety measures.

- Proactive Safety Systems

- process improvement

- Professional development

- propane safety

- propane storage

- protective clothing

- psychological hazards

- psychological safety

- PsychologicalSafety

- quality control

- quality management

- quality standard

- Real Safety Leadership

- real-time hazard reporting

- Real-Time Reporting

- real-time safety

- real-time safety tools

- real-time site data

- recordkeeping

- reduce training costs

- regulatory updates

- repetition in safety

- repetitive motion injuries

- respirator safety

- respirators

- Respiratory Protection

- risk assessment

- risk management

- risk mitigation

- risk prevention

- Risk Prevention Tools

- risk reduction

- road safety

- Robin Postnikoff

- ROI with AI

- root cause analysis

- root cause correction

- routine task risks

- safe excavation

- safe habits

- safe transport

- safe work habits

- safe work practices

- safety

- safety accountability

- safety advice

- safety analytics integration

- safety article

- Safety Audit Software

- safety automation

- safety automation tools

- safety awareness

- Safety Behaviour

- safety behaviour science

- safety best practices

- safety communication

- safety compliance

- safety consulting

- Safety Conversations

- safety culture

- safety culture transformation

- safety data

- safety data sheets

- safety documentation

- safety engagement

- safety follow-up

- safety gear

- safety gloves

- safety goggles

- safety habits

- safety improvement

- safety incentives

- safety innovation

- safety insights

- safety inspection

- safety instinct

- Safety Leaders

- safety leadership

- Safety Leadership Podcast

- safety legislation

- safety lessons

- safety management

- safety management software Canada

- safety management system

- safety management systems

- safety metrics

- safety mindset

- safety motivation.

- safety myths

- safety onboarding

- safety planning

- safety podcast

- safety procedure updates

- Safety Procedures

- safety process improvement

- Safety Professional Development

- safety professionals

- Safety Programs

- safety reporting

- safety review process

- safety shortcuts

- safety software

- safety software evaluation

- Safety Spotlight

- Safety strategy

- safety systems

- safety technology

- safety technology buyers guide

- safety theater

- safety tips

- safety tools

- safety training

- safety transformation

- safety transparency

- Safety Without Blame

- SafetyCulture

- SafetyLeadership

- Sarah Anderson

- scaffold safety

- scaffolding inspections

- Scalable Safety Programs

- scalable training solutions

- Scott Lyall

- SDS

- shipping documentation

- silent dangers

- silica dust

- Silica Exposure

- Silicosis Prevention

- Sinogap Solutions

- slips trips falls

- slow-building hazards

- smart helmets

- smart PPE

- smart safety systems

- smart safety tools

- Social Learning

- SOPs

- space science

- speak-up culture

- Spencer McDonald

- Standardized Work

- stop work authority

- storytelling and safety

- storytelling in safety

- supervisor training

- system safety

- Systems Thinking in Safety

- tablet-based toolbox talks

- Tank Cleaning Safety

- TCP safety

- TDG

- team communication

- team performance

- teamwork

- tech and ergonomics

- tech in safety

- tech-enabled learning

- The Safety Spotlight

- Thinking Driver

- Titan Environmental

- Tom Krause

- toolbox talks

- toolbox talks tablets

- Total Buy-In

- Total Recordable Injury Formula

- tough guy mentality

- toxic air

- Toyota Motor Manufacturing Canada

- traction control

- traffic control

- traffic control plan

- training

- training courses

- Training integration

- training management

- training matrix

- training record management

- training records

- training software

- TrainingAndDevelopment

- transportation

- transportation of dangerous goods

- Transportation Regulations

- Transportation Safety

- Trucking Regulations

- trust

- Trust & Accountability

- Trust & Communication

- Trust and Accountability

- trust at work

- Tyler Foley

- Underground infrastructure

- underground utilities

- unseen workplace threats

- Upward communication

- user experience

- utility line marking

- utility locating

- Utility safety

- Utility Safety Partners

- values-based onboarding

- vehicle safety

- version control

- veteran advice

- Virtual Reality

- VR safety training

- VR Technology

- walkway maintenance

- wearable technology

- Weights and Dimensions

- Wellness at Work

- WHMIS

- Wildlife awareness

- winter safety

- witness statements

- women in leadership

- work zone safety

- work-alone training

- work-related injuries

- worker accountability

- worker advocacy

- Worker buy-in

- Worker Engagement

- worker fatigue

- Worker Health

- worker protection

- worker safety

- worker safety habits

- worker safety tips

- Worker Safety Training

- worker trust

- worker wellbeing

- workers' rights

- Workforce Automation

- workforce compliance

- Workforce development

- workforce engagement

- workforce management

- Workforce Readiness

- workforce training

- Working Alone Canada

- workplace accidents

- workplace air quality

- workplace best practices

- workplace certification

- workplace compliance

- Workplace Culture

- workplace hazard prevention

- Workplace Hazard Tracking

- workplace hazards

- workplace health

- workplace incident response

- workplace injuries

- workplace injury prevention

- workplace inspections

- workplace leadership

- Workplace Mental Health

- workplace mindset

- Workplace Organization

- workplace readiness

- workplace risk factors

- workplace risk management

- Workplace Risk Mitigation

- Workplace safety

- Workplace Safety Compliance

- workplace safety culture

- Workplace Safety Leadership

- workplace safety rules

- workplace safety tech

- workplace safety tips

- Workplace Safety Tools

- workplace safety training

- workplace stress

- workplace tiredness

- workplace trust

- workplace wellness

- WorkplaceSafety

- Worksite Safety

- WSPS

In this Safety Spotlight episode, Darren Varga breaks down why “safety first” is not enough, exploring how trust, worker voice,...

In this Safety Spotlight episode, Nayab Sultan explores the hidden risks of silica exposure, examining how overlooked hazards, misdiagnosis, and...

In this Safety Spotlight episode, Rick Sikora of Cranemasters challenges the idea of “common sense” in safety, exploring how true...