BIS Safety Software

Equipment Management Software

Streamlining Your Equipment Information

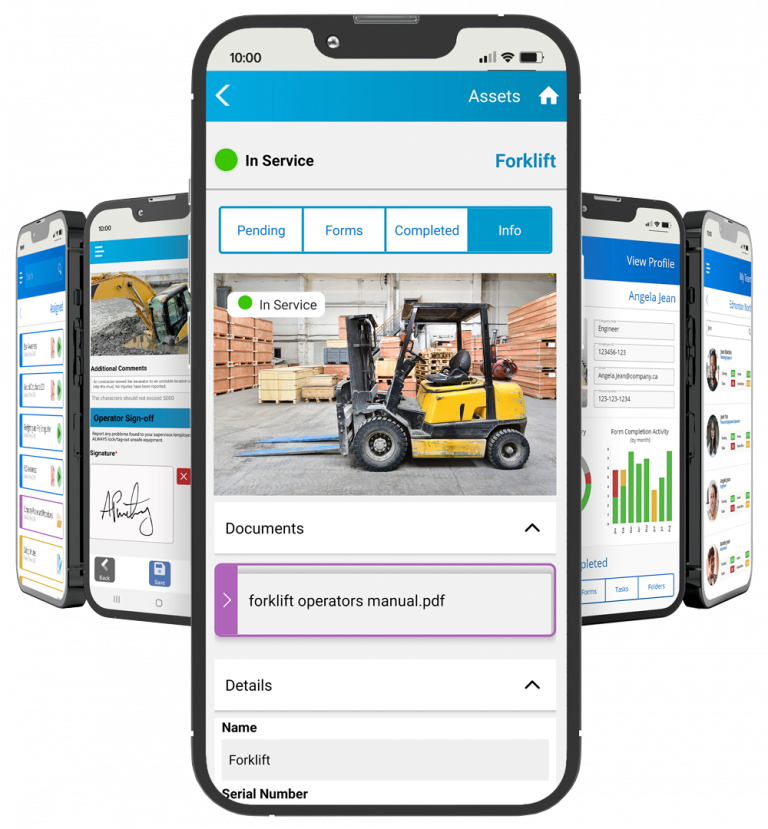

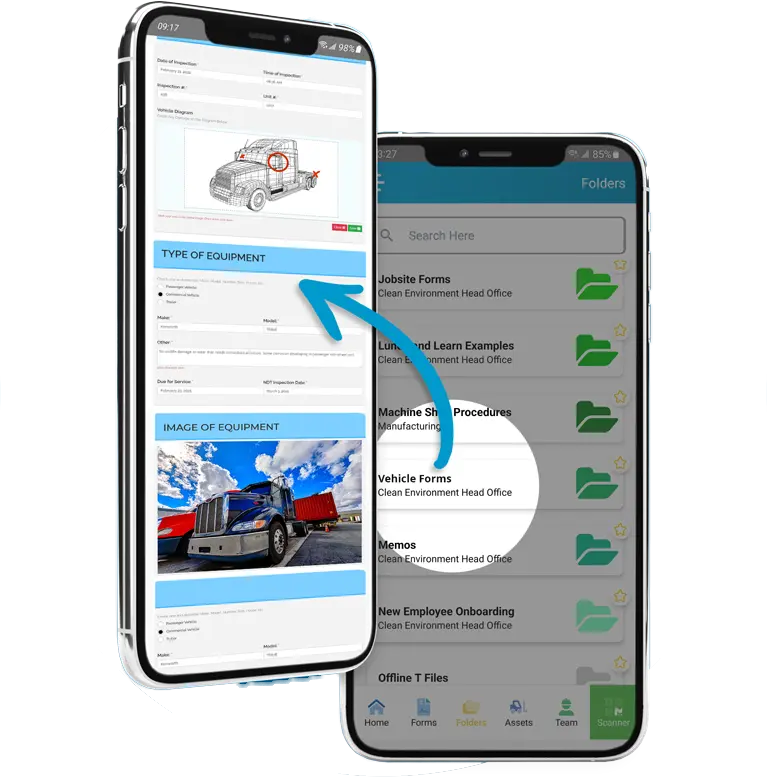

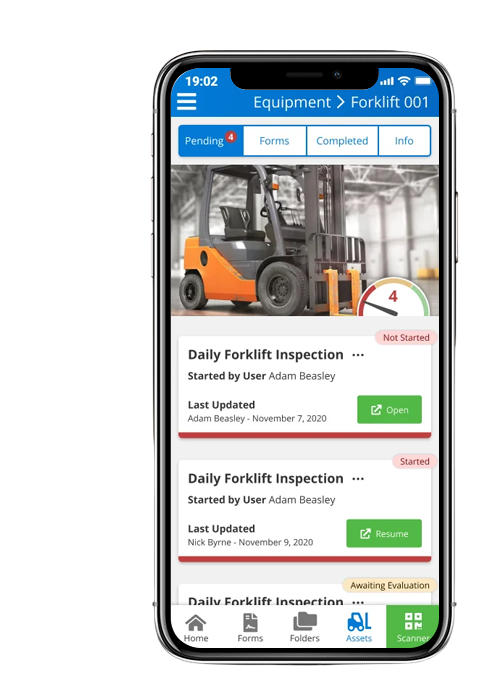

Access Equipment/Asset Information with Your Phone

Integrated QR Codes

Ensuring consistent and fair competency assessments while maintaining easily accessible records for future reference. Utilizing software simplifies the entire process. With a mobile app or software, you can conduct comprehensive competency assessments and store all the results securely in the cloud. This allows administrators to quickly access the reports whenever needed.

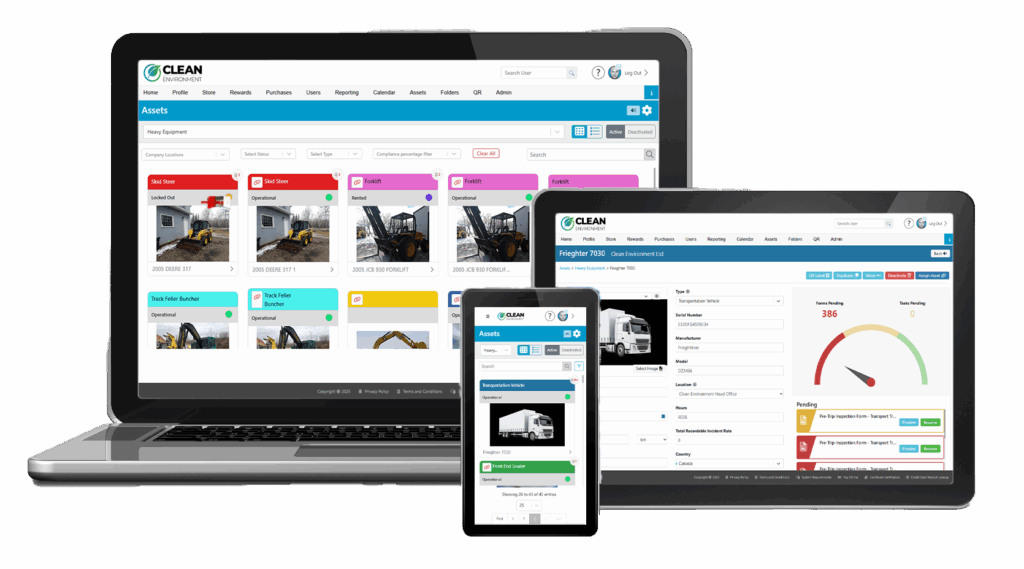

Asset Management

Streamlining Equipment Tracking

Tracking equipment conditions and inspections can be time-consuming, but with instant access to real-time data from any device, staying on top of maintenance has never been easier. Our cutting-edge asset management software goes beyond simple location tracking, giving you a complete view of equipment status, inspections, and performance.

Authorized Personnel

Effortless Personnel Tracking

Easily assign personnel to specific equipment and automate reminders for inspections and compliance tasks. Whether it’s pre-shift checklists or weekly maintenance, our asset management system ensures everything is completed on time, keeping your workforce accountable and your operations running smoothly.

Measurable Mileage

Efficiency in Mileage Tracking

Keep track of the distance travelled by each piece of equipment by entering and reviewing its mileage in miles or kilometres. Set up schedules for inspections and safety-related maintenance forms, so that when certain mileage milestones are reached, qualified personnel receive notifications to complete the required forms.

Hours Management

Seamless Hours of Operation Tracking

Record and monitor the number of hours each piece of equipment has been in use. Then, establish completion requirements for inspections and maintenance safety forms based on predefined milestones of operating hours. This ensures that your machinery adheres to the inspection and maintenance standards set by the manufacturer.

Dependable Data Management

Insights through Advanced Analytics

Leverage the data from your tracked information to simplify job planning. Identify which equipment is causing issues, determine the most frequently used machinery, and pinpoint the locations where specific pieces of equipment are in high demand. Monitor the progress of any identified aesthetic, mechanical, or safety concerns through a shared document.

Predictable Equipment Management

Proactive Maintenance Scheduling

Stay ahead of equipment issues with proactive maintenance scheduling. Our equipment management system enables you to create automated maintenance plans based on usage hours, mileage, or custom intervals. By setting reminders for routine inspections and servicing, you can reduce downtime, extend equipment lifespan, and prevent costly repairs. Keep your operations running smoothly with a structured, data-driven approach to equipment upkeep.